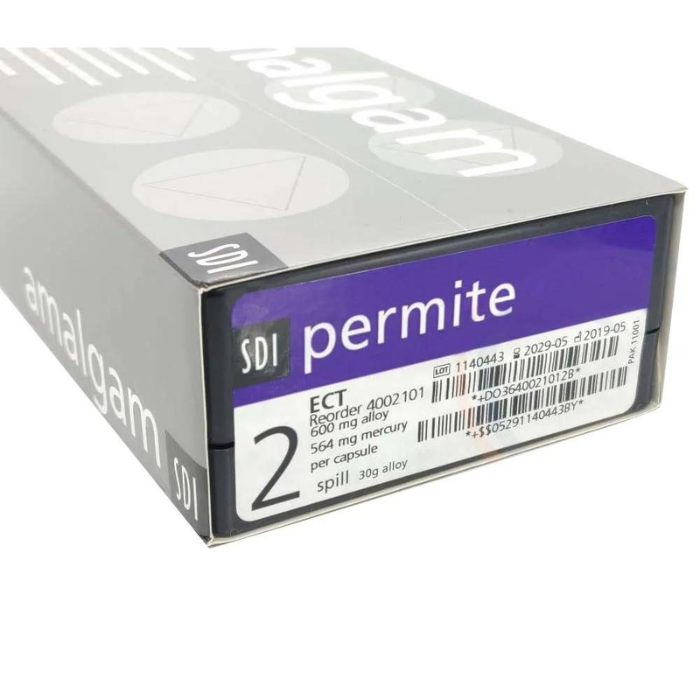

Sdi Permite Capsules Spill 2 (4002101)

Permite offers superior sealing qualities and is resistant to excessive delayed expansion when contaminated with water-based fluids, making it an ideal choice for retrograde fillings. It combines high strength, polishability, and excellent handling characteristics.

Permite is a non-gamma 2 admix alloy that stands unmatched in its category.

- High Compressive Strength: Ensures a durable and long-lasting restoration by minimizing the risk of fractures.

- Low Microleakage: Virtually zero microleakage reduces the risk of postoperative sensitivity.

- Moisture Resistance: Provides excellent sealing qualities without the risk of excessive delayed expansion.

Indications:

Permite is indicated for the restoration of carious teeth.

Features:

- High Compressive Strength: Permite’s high compressive strength minimizes the risk of restoration fractures, ensuring a durable and long-lasting result.

- Low Microleakage: Permite has virtually zero microleakage, reducing the risk of postoperative sensitivity often associated with extensive microleakage.

- Optimal Handling Characteristics: Permite received a 98% rating from Dental Advisor Plus for mix consistency, ease of loading, placement, condensability, burnishability, quality of interproximal contact, carvability, and setting characteristics. The resulting restorations are smooth with excellent margin adaptation, especially after burnishing. All consultants would recommend Permite to their colleagues.

- Moisture Resistance: Permite demonstrates excellent sealing qualities and is not prone to excessive delayed expansion when exposed to water-based fluids, making it ideal for retrograde fillings.

- Variety in Setting Times and Capsule Sizes: The flexible working and setting times allow for the easy condensation and carving of large restorations, and a wider selection of capsule sizes is available.

| Technical Specification | Composition Ag 56%, Sn 27.9%, Cu 15.4%, In 0.5%, Zn 0.2% (Contains zinc in an alloyed form, not free zinc) Warnings

CAUTION: Federal law restricts this device to sale by or on the order of a dentist.

|

|---|

- Box of 50 Capsules

STEP 1:

- Isolate tooth.

STEP 2:

- Prepare cavity using standard technique for amalgam restoration.

Note: In cases where pulp protection is necessary, use a calcium hydroxide liner or glass ionomer cement.

STEP 3:

- Activate a capsule on a bench or hard surface until plunger is fully flushed with the body of the capsule.

STEP 4:

- Place activated capsule in a high speed multi-use triturator.

STEP 5:

- Triturate capsule as per recommended in Table below.

Mechanical Amalgamation Mixing Time Requirement:

Amalgamator Speed Permite

| Ultramat 2 (SDI Ltd.) | Fixed (4600 rpm) | 1, 2 & 3 spill | 5 spill |

| 8 ± 1 sec | 6 ± 1 sec | ||

| Ultramat 2 (SDI Ltd.) | Fixed (450 rpm) | 1, 2 & 3 spill | 5 spill |

| 8 ± 1 sec | 6 ± 1 sec |

STEP 6:

- Carefully remove the triturated capsule from the triturator and gently tap the base on a bench or hard surface once.

STEP 7:

- Open the capsule by removing the base from the body to access the prepared amalgam.

Note: Freshly mixed amalgam should have a bright look and a plastic consistency.

STEP 8:

- Immediately insert amalgam into prepared cavity using a clean amalgam carrier employing standard amalgam condensation technique.

Note:

i. “If moisture is introduced into the dental amalgam before it has set, properties such as strength and corrosion resistance can be affected adversely. If the alloy contains zinc, such contamination can result in excessive expansion (delayed expansion). Use a dry field, whenever it is possible.

ii. Permite contains zinc in an alloyed form and not free zinc. It’s the free zinc which is very sensitive to moisture.

STEP 9:

- Remove any mercury rich amalgam from the surface that may develop during condensation.

STEP 10:

- Trimming and carving can begin after condensation using a sharp carver.

STEP 11:

- Light burnishing can be carried out after 24 hours to improve surface smoothness. Avoid over heating by ensuring adequate water cooling and low speed.